Revolutionizing the manufacturing industry with technology

Manufacturers across the globe now understand that to compete in today’s technology-oriented environment, they need to have efficient software solutions. However, technology solutions are complex and in abundance. Manufacturers often have trouble deciding which solution addresses their current and future needs. That’s where AlphaBOLD comes in! We are technology advisors dedicated towards helping manufacturers select a software solution best suited to their needs.

Manufacturing 4.0 – the shift to digital transformation

Manufacturing 4.0 is a digital revolution powered by software solutions, sensors, connectivity, and big data analytics. The maturation of digital technology in the manufacturing industry has enabled business owners to increase product quality at a lower operating expense. These new industry applications have transformed the way manufactured goods are planned, designed, made, and repaired. As the winner of the Microsoft Partner Award for Dynamics 365 Customer Service, AlphaBOLD has remained at the forefront of this revolution providing leadership in customer impact, solution innovation, and exceptional use of modern technologies.

Solutions built for the manufacturing industry

BOLDConnect

BOLDConnect is an end-to-end predictive maintenance solution that uses artificial intelligence and smart sensors to improve operational efficiency, minimize costs, and extend the equipment lifecycle. By connecting IoT devices with business processes, you can monitor the health and performance of your industrial equipment anytime, anywhere.

Behavioral CRM

Behavioral CRM is a connected system that enables sales and marketing to work together efficiently. The solution provides them with improved insights and efficient sales collaboration, thus empowering them to execute the sales strategy effectively. With tailored information, improved tracking, access to data, and time efficiency, the Behavioral CRM improves the overall sales and profitability of the company.

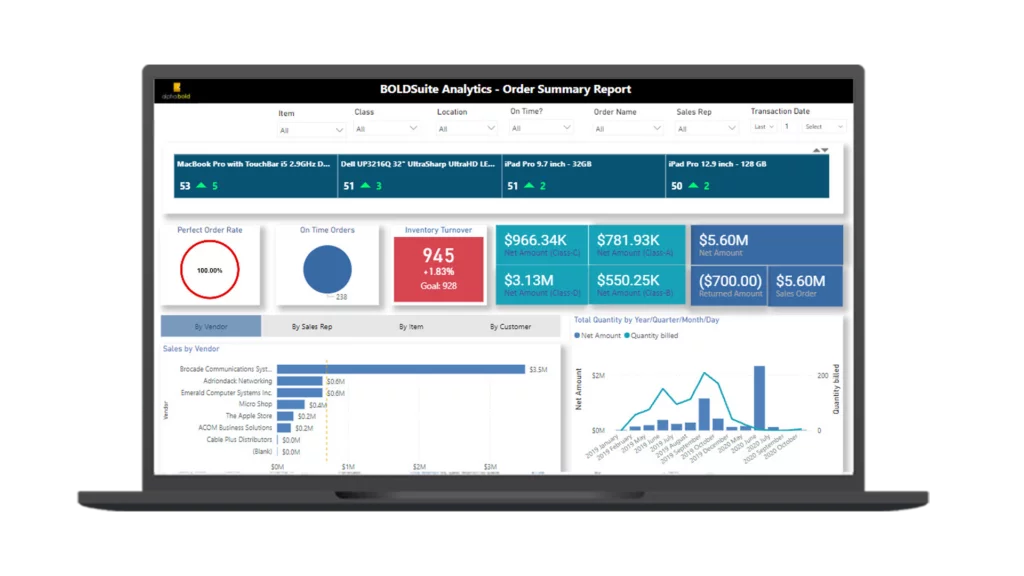

BOLDSuite Analytics

BOLDSuite Analytics is a Power BI connector that can pull data into the Power BI environments and merge them with other sources. We have developed multiple out-of-the-box reports to cater to the exact needs of all our clients across industries. The reports quickly load up-to-date data and tailor it to the clients’ exact requirements.

Complex manufacturing implementations

By utilizing state of the art technology, AlphaBOLD helped manufacturing companies foster innovation and success.

managing inventory & supply chain

Challenges

Solution

Impact

- Inventory management done through excel spreadsheets

- Manual and disparate reporting processes

- Lack of order tracking visibility

- Integration with existing ERP

- Customer Service Implementation

- Unified global and regional approaches

- Integrated data sources to improve visibility

- Streamlined order management process

- Optimized data management

- Efficient delivery tracking

- Enhanced customer service workflows

- Improved data structure, speed, and actionability of incoming orders

managing inventory & supply chain

Challenges

- Inventory management done through excel spreadsheets

- Manual and disparate reporting processes

- Lack of order tracking visibility

- Integration with existing ERP

Solution

- Customer Service Implementation

- Unified global and regional approaches

- Integrated data sources to improve visibility

- Streamlined order management process

Impact

- Optimized data management

- Efficient delivery tracking

- Enhanced customer service workflows

- Improved data structure, speed, and actionability of incoming orders

revamping the contact center solution

Challenges

Solution

Impact

- Outdated customer processes

- Disconnected and delayed processes

- Reliance on manual case management

- Integration with existing ERP

- Unified Service Desk and Dynamics 365

- Data ingestion for complete visibility

- Customized and automated workflows

- Integration of existing ERP with new tools

- Enhanced productivity of call center operations

- 360’ view of customer information

- Cost and time efficiency

- Improved resource utilization

- Reduced complaint lifecycles

revamping the contact center solution

Challenges

- Outdated customer processes

- Disconnected and delayed processes

- Reliance on manual case management

- Integration with existing ERP

Solution

- Unified Service Desk and Dynamics 365

- Data ingestion for complete visibility

- Customized and automated workflows

- Integration of existing ERP with new tools

Impact

- Enhanced productivity of call center operations

- 360’ view of customer information

- Cost and time efficiency

- Improved resource utilization

- Reduced complaint lifecycles

substantial growth with future ready technology

Challenges

Solution

Impact

- Lack of visibility and poor reporting

- No industry-specific configurations Complex accounting processes

- Scalability limitations due to an outdated legacy system

- ERP implementation

- Switching from average cost to standard cost accounting

- Updating technology infrastructure

- A solution that scales alongside the business

- Cost and time efficiency

- Increased visibility and improved reporting

- Improved resource utilization

- Streamlined accounting processes

substantial growth with future ready technology

Challenges

- Lack of visibility and poor reporting

- No industry-specific configurations Complex accounting processes

- Scalability limitations due to an outdated legacy system

Solution

- ERP implementation

- Switching from average cost to standard cost accounting

- Updating technology infrastructure

Impact

- A solution that scales alongside the business

- Cost and time efficiency

- Increased visibility and improved reporting

- Improved resource utilization

- Streamlined accounting processes