Build-to-order and engineer-to-order manufacturing processes focus on building or designing finished products after an order is received. These production scenarios may apply to companies that produce tailored medical devices or custom industrial equipment and machine components. This article is relevant to manufacturing companies that process custom orders with frequent changes to product design and specifications.

To fulfill orders quickly, the production managers and engineers often need a rapid, just-in-time method of constructing a Bill of Materials (BOM) and sending the BOM specification and the traveler to the production floor.

ERP systems require the Assembly Item / BOM to be pre-configured and generated before it can be added to the Sales Order and subsequently a Work Order. This step is often cumbersome and predicated on some understanding of the item’s accounting impact before it can be completed. As a result, production managers and administrators often struggle to configure the Assembly Item correctly and this introduces unnecessary delays in the order fulfillment.

After some research and deeper discussions with our clients, we saw a need to develop a tool on top of NetSuite’s platform that will allow users to easily generate Assembly Items from the order screen.

In this article, I will walk you through our BOM Generator tool in hopes that it may inspire you to add new efficiencies to your production. We believe that BOM creation in NetSuite should be simple, intuitive and fast.

I will start by:

- Explaining how the tool works

- Its configuration

- Its features and improvements in works

How does it work?

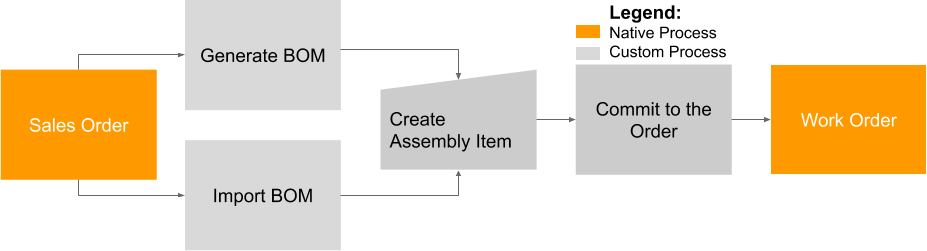

The following diagram illustrates the basic, high-level process of creating Assembly Items directly from the order screen.

Let’s walk through this in detail.

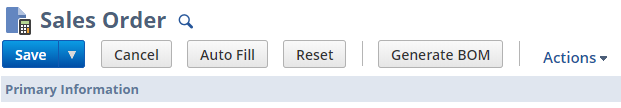

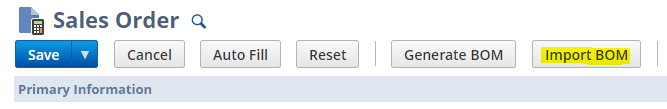

- When a Sales Order is in the ‘edit’ mode and while it’s pending approval, the user will see [Generate BOM] button.

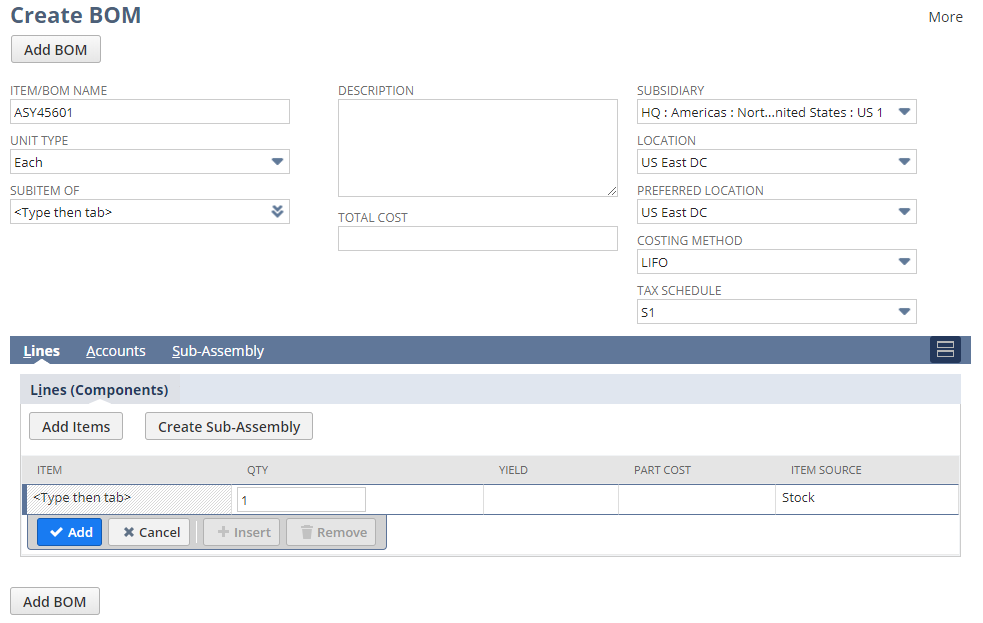

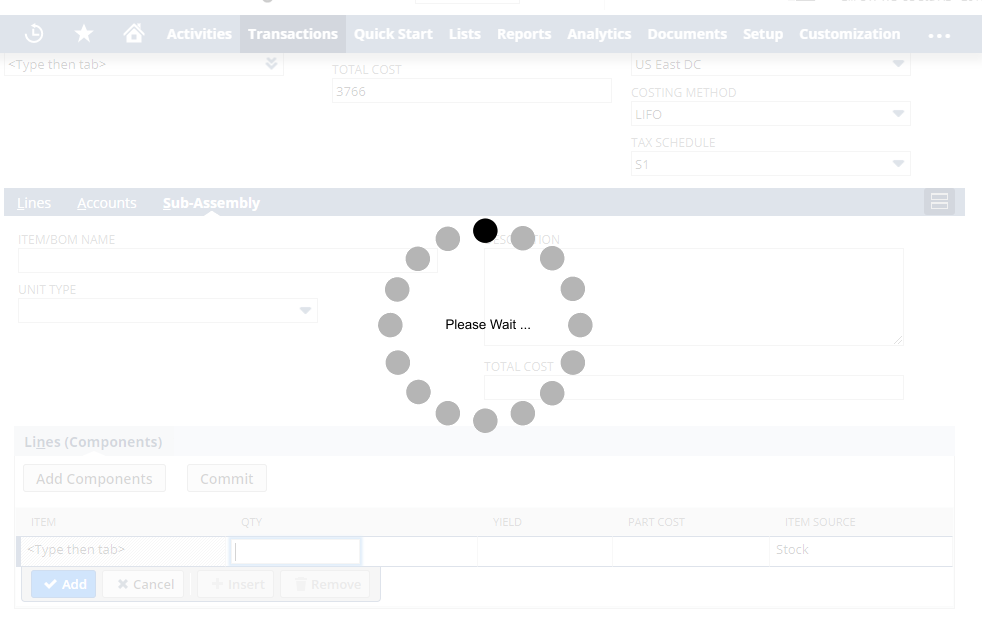

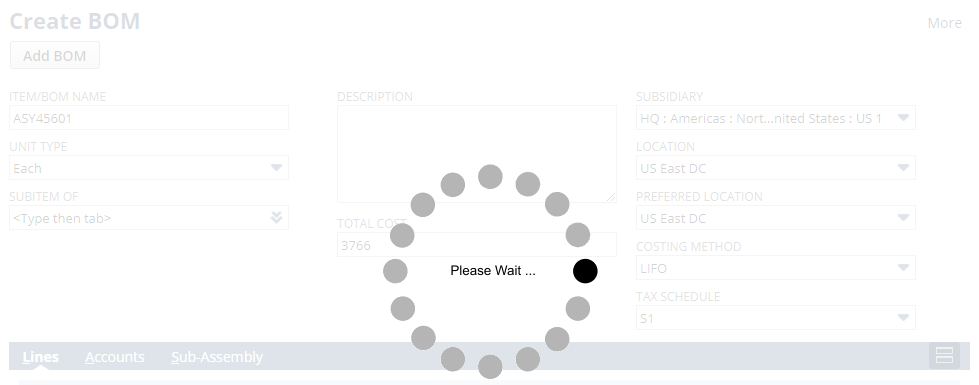

- By clicking the [Generate BOM] button, a pop-up screen will appear.

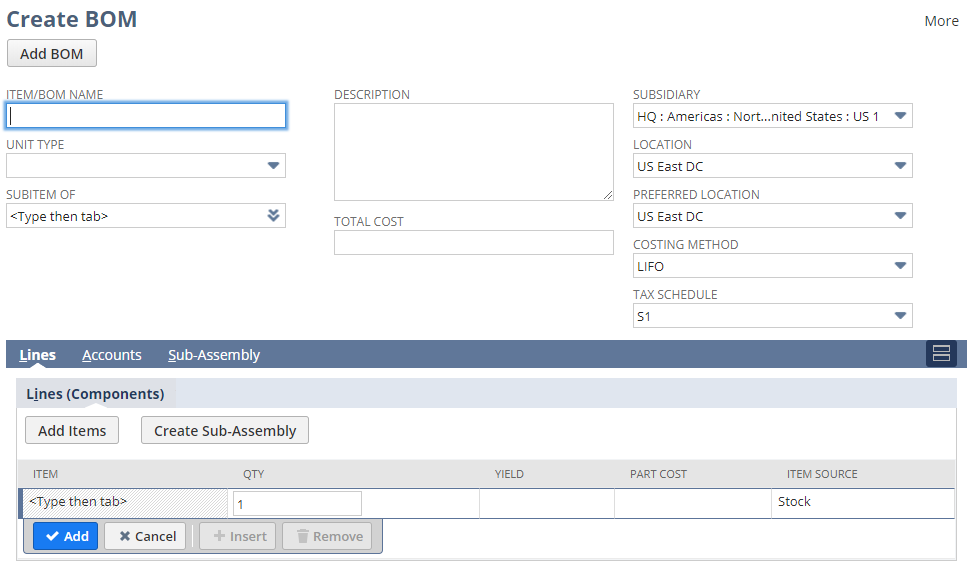

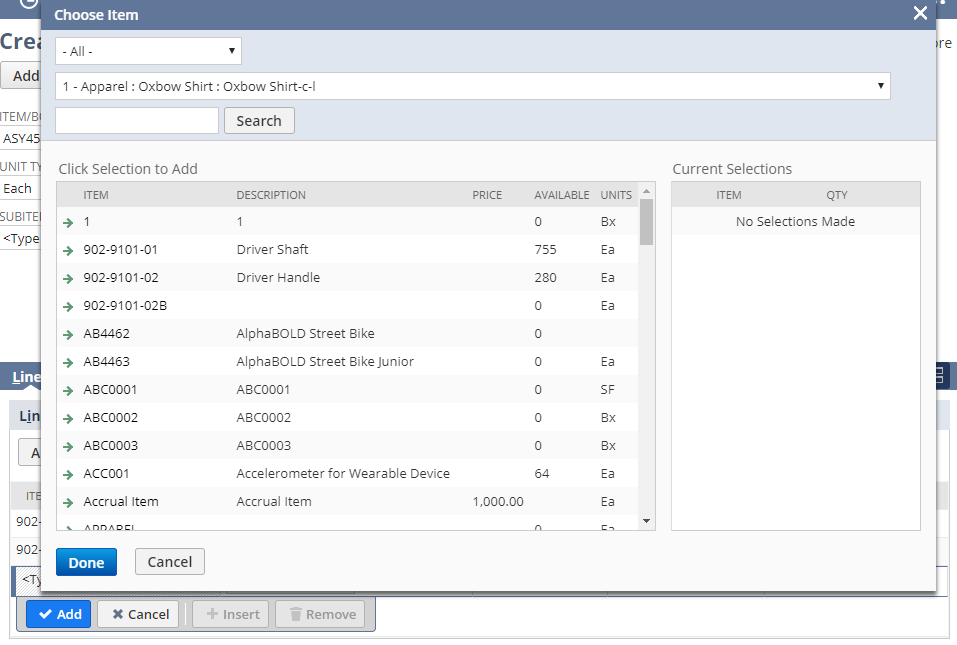

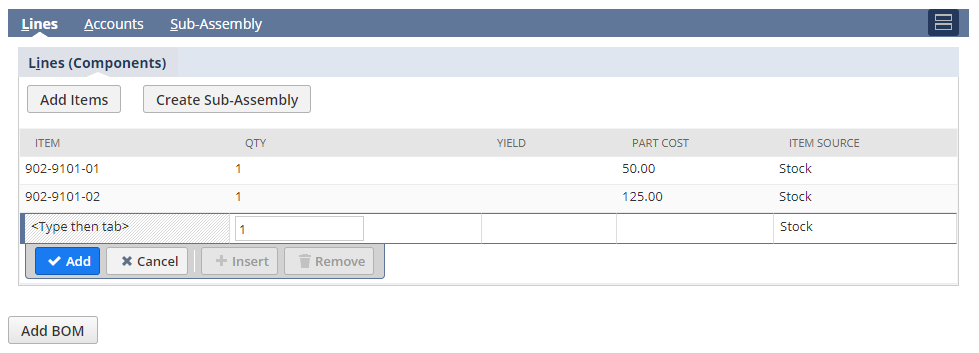

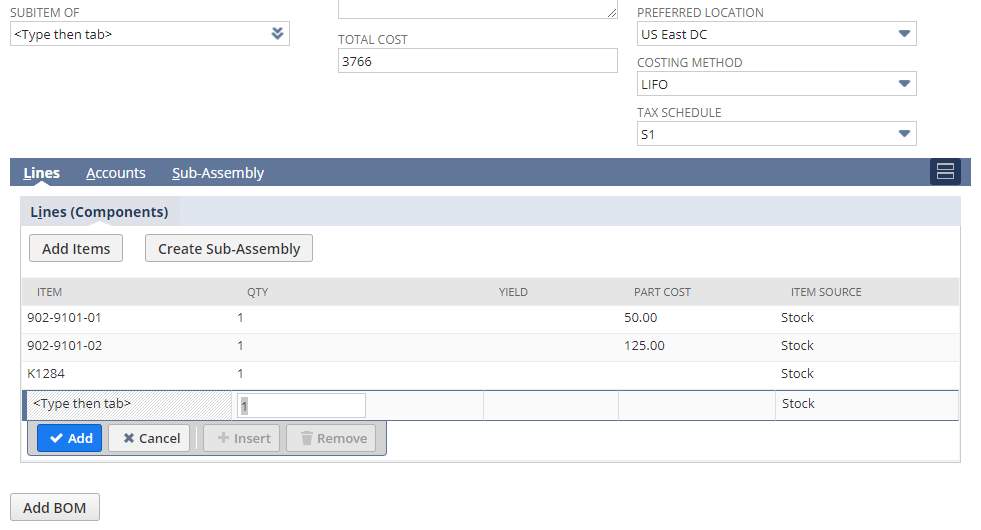

- The user can enter the new SKU number in the ‘Item/BOM name’ field and then start selecting the components for this Assembly Item record ([Add Items] button).

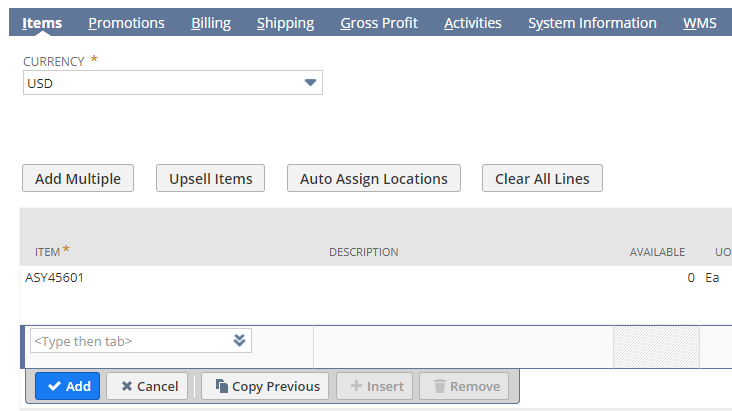

- By clicking on [Add BOM] button, the user can create an Assembly Item in the system and add it to the order line.

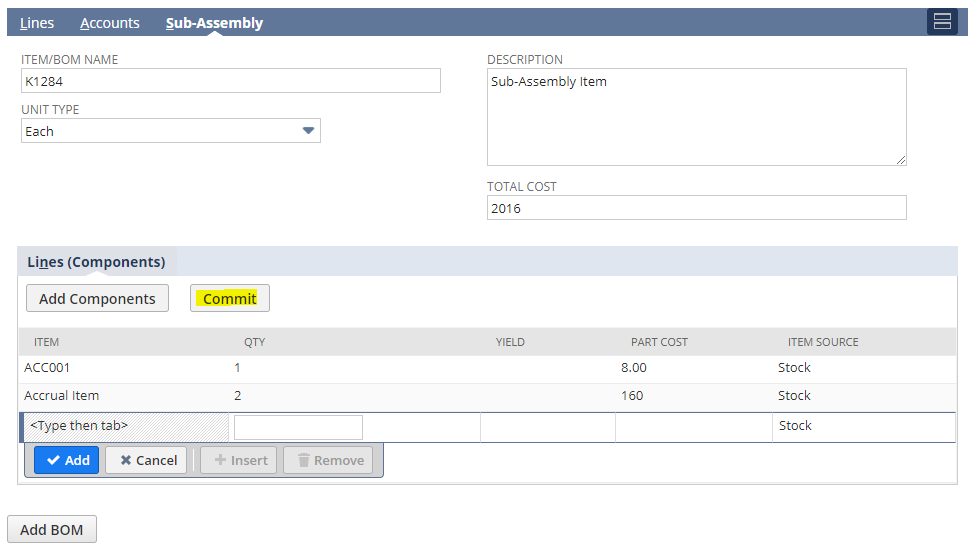

- Without navigating away from this screen, the user can also generate Sub-Assemblies. These will be added as components to the parent BOM.

- Clicking on [Add BOM] button will generate Item / BOM record and then complete the process.

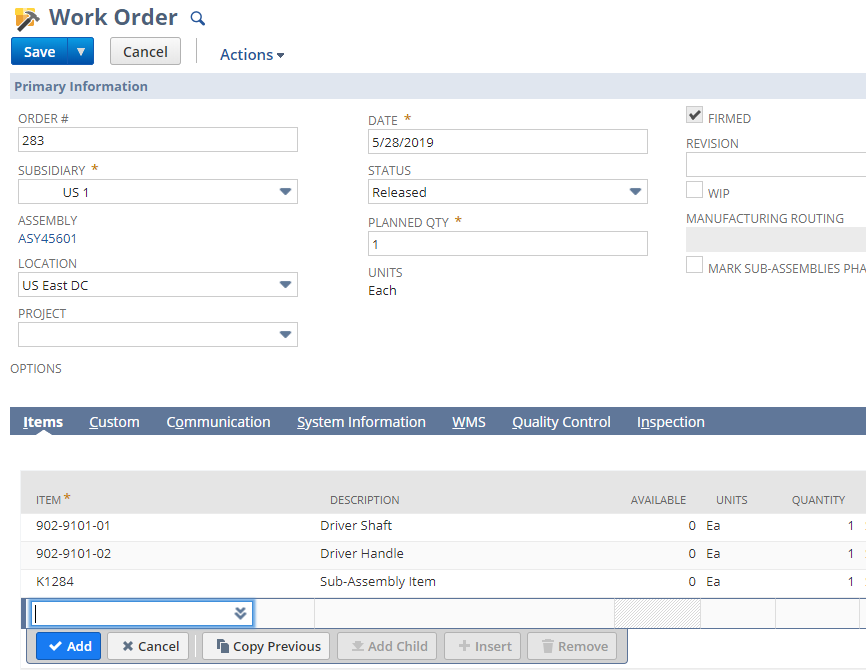

- The order can be finalized and saved. From the order, the production manager may decide to create a Work Order and send the traveler to the production floor.

- You will notice that all the components are sourced automatically from the Assembly Item.

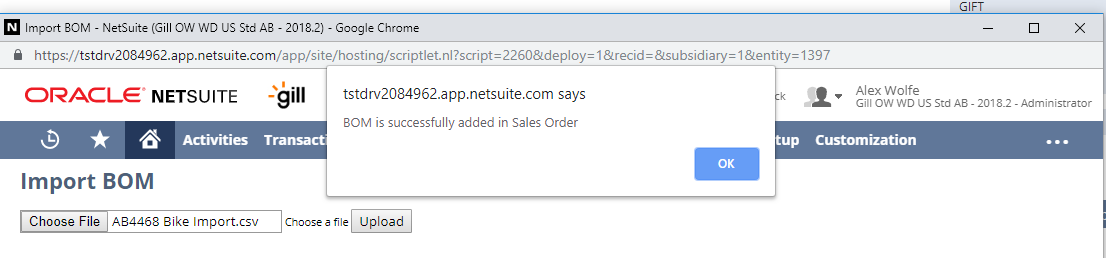

CSV Import

We added a new feature to the app that allows you to create items through a CSV file upload capability. The CSV import is available on the Sales Order page or as a stand-alone interface.

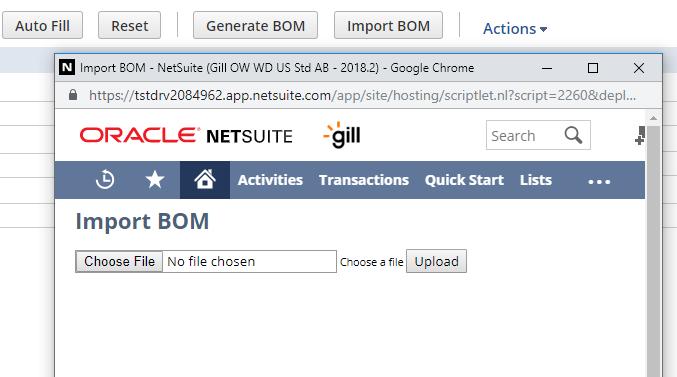

- When the button is clicked a new interface will appear that allows the user to upload a CSV file.

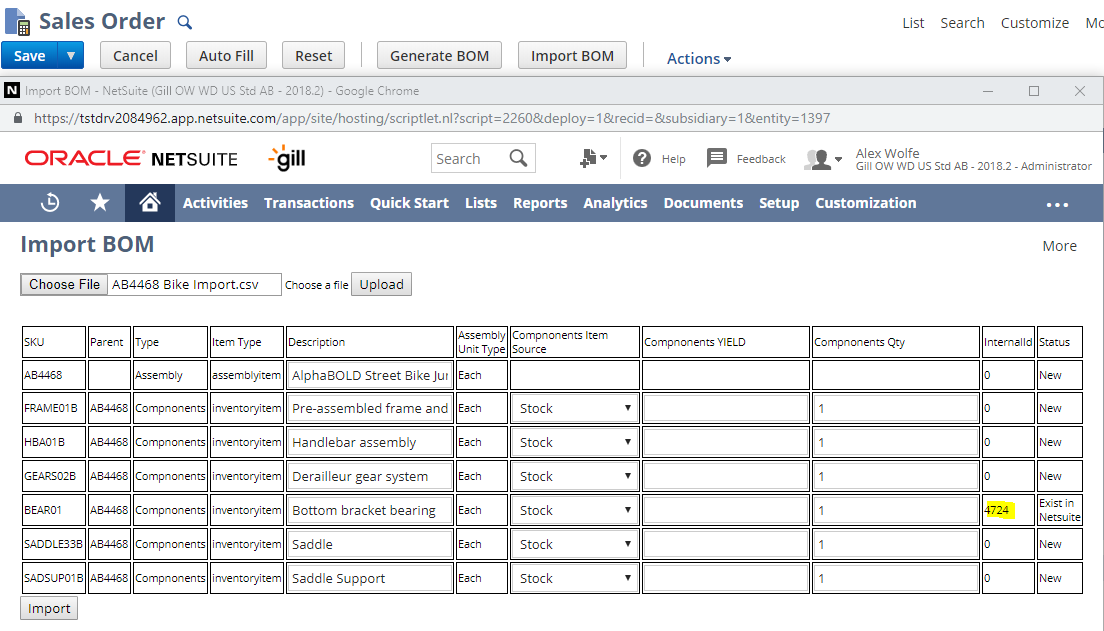

- When the file is selected and uploaded an intelligent grid will appear that will allow the users to adjust the items before they are imported in the system.

- Notice the status column. if a product exists in the system the grid will detect it and it won’t import it. Once the [Import] button is clicked, the app will generate one or more Assembly Items in the system and it will add these to the order.

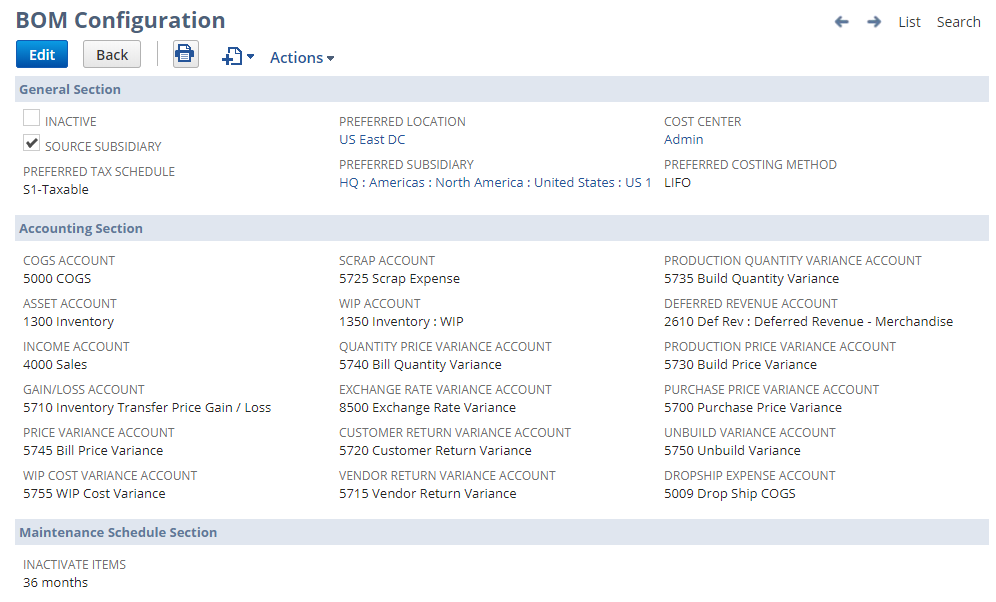

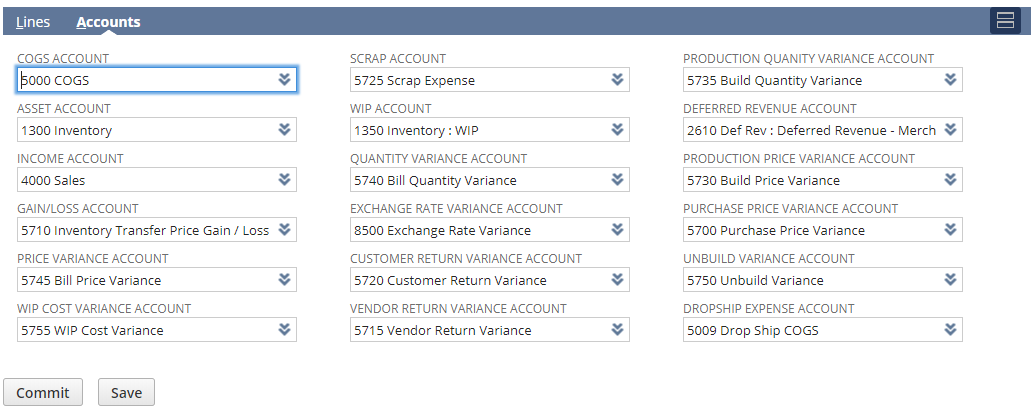

Configuration

The item defaults are managed through a configuration record.

- Note, mandatory fields are sourced from the configuration record and are set right after the installation of our bundle.

- If the location is not set on the Sales Order, the location is sourced from the configuration record.

- The solution will list selectable components based on the subsidiary entered / sourced on the ‘Create BOM’ window. This maintains the system integrity and avoids errors.

- Accounts are defaulted from the configuration page but can be overridden during the BOM generation step.

- Lastly, the maintenance schedule section is tied to a schedule script that inactivates items that have not been used on any transaction for an extended period. The goal is to keep the system clean and your system’s performance optimal. Options from 1 to 36 months are available.

Features and Future Enhancements

Currently, the following features are supported by this solution

- Ability to create from 1 to 100 Assembly Item SKU’s from ‘Create BOM’ interface.

- Ability to create Sub-Assemblies from the same screen*

- The ‘Create BOM’ interface can be used as a stand-alone form or from the Sales Order screen.

- Bundle installer is available, some configuration is required (Configuration Record)

- Maintenance scheduled routine inactivates unused items.

- CSV Import Tool for importing BOM(s) from external CAD systems*

- Component and BOM cost tracking while building the Assembly Item*

* Newly added features.

Future Enhancements

- Additional support for process manufacturing (formula and recipe records)

- Route defaulting for WIP and operations view

- BOM mass change screen (mass update of BOM components)

- CAD file conversion using the CSV Import tool

Thank you for your attention and feel free to comment on this functionality and request additional features. Our goal is to add as many features as possible, all the while keeping ‘BOM Generator’ simple and easy to use.